A Hybrid PLM Experience for the Apparel and Footwear Industry

Table of contents

Apparel and Footwear process are similar in nature. Both share the common aspects of fashion, seasonality, extended supply chain and low-cost labor.

The adoption rate of PLM in Apparel brands are significantly higher compared to their Footwear counterpart, due to the sheer volume of the Apparel business in the world and also apparel brands realized the facts that PLM is a business-critical system for the innovation and profitability.

Traditional PLM vendors offer solutions based on their Apparel experience to Footwear brands and it will be a major challenge to the footwear designers/developers to embrace the PLM system.

Footwear brands are now rethinking their PLM strategy and looking for a hybrid solution to lower the cost of ownership and a single source of truth to cater the needs of two divergent user communities under a single brand.

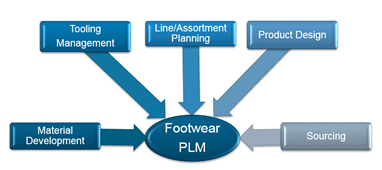

Figure 1: Footwear PLM process

Material Development

Fabric development is very critical for the Apparel companies and the traditional Apparel PLM vendors provide a detailed process for the planning, testing, yardage request, lab dips, strike-offs and bulk fabric request.

80% of garment cost is coming from fabric alone. Apparel PLM materials (Fabric, Trim and Embellishments etc.) are managed in libraries with a seasonal cost for a tighter control of the cost.

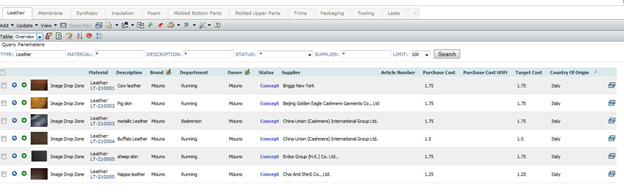

Footwear, on the other hand, has no Fabric development. Material libraries in the Footwear PLM to be broken down quite differently as they demand a complex hierarchy e.g. upper, lining, insole, outsole and other key components.

Figure 2: Footwear Material Libraries

Tooling Management

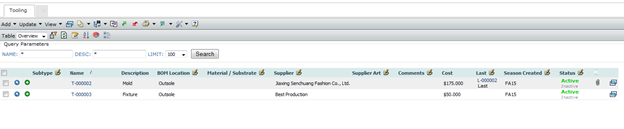

Tooling is an important aspect of the footwear industry. Each shoe design needs a last and molds to shape the shoe.

The tooling is quite unique to the shoe design and thus driving the cost. Gender plays an import aspect in the footwear tooling decisions as the women’s fashion shoes, heels are a custom item.

Tooling is very critical in style development. Footwear PLM must have last and tooling libraries and also process to track the usage, refurbishment cycle and cost.

Figure 3: Tooling Library

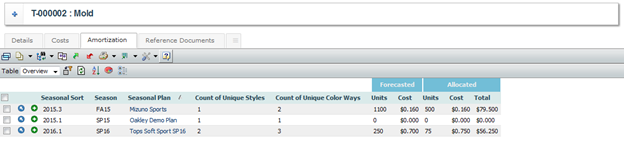

Last making is an art and a carefully designed last with clear points of measure plays a significant role in the in-season fitment session and pre-production runs. Lasts and outsole molds are not cheap. That cost needs to be amortized across the expected production run of the style, a concept that does not exist in apparel.

Figure 4: Tooling cost amortization

Line/Assortment Planning

Product planning is very critical for both the Apparel and Footwear industry. The planning should support multiple regions and show clear visibility of the style adoption and the profit margins.

Apparel and Footwear brands are looking for the following capabilities in the PLM solution:

- Global visibility of the plan and development status

- Global assortment of the products, quantity, color and size

- Regional adoption of the products

- Margins and profitability

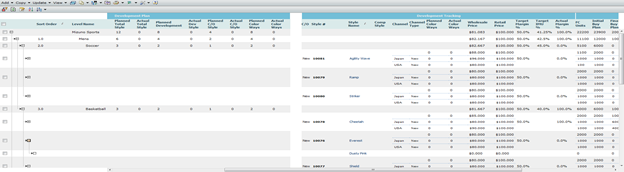

Figure 5: Multi-level line plan with profit margins

Figure 6: Global visibility of region/style/cost

Figure 7: Global Plan with actual vs. Planned

Figure 8: Global plan with style/regional assortment

Product Design & Development

Styles are managed differently in both Apparel and Footwear business. For apparel companies, there are seasons and/or lines, seasonal groups, collections, possibly sub-collections and then styles and their associated size ranges. Footwear companies have seasons and/or lines, styles, sizes and widths.

Apparel and Footwear BOMs are significantly different. In the apparel process, the designer/developer adds a raw material to the product and then defines the ‘location’ it is used for. E.g. Fabric first and then placements of that fabric (sleeve, collar, pockets, as examples).

In the footwear process, the designer/developer adds a component location (Vamp, Quarter, and Heel) to the product and then assign a material to it later on in the development process. This fundamental difference dictates the approach and mindset of the developer, their expectations of the system and the usability experience built into the application.

A traditional Apparel PLM vendor will be struggling to deliver the competitive solution without significant customization.

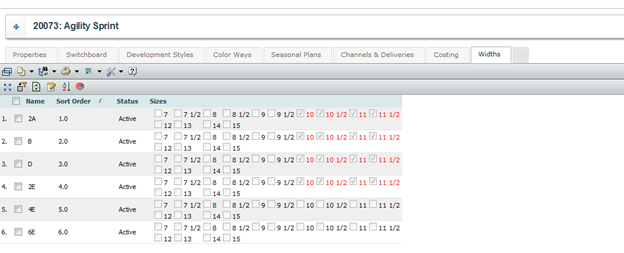

Figure 9: Advanced Footwear BOM

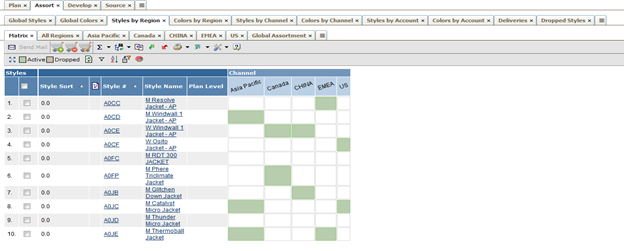

Figure 10: Size/Width grid

Sourcing

Sourcing strategy and thus the supply chain management is different in both industries, in a typical apparel business sourcing decisions are driven by the tariff and customs regulations. It is quite common that semi-finished garments are shipped to the warehouse and packaged before shipping to the distribution center.

Apparel cost sheets are designed to manage split garments cost and then calculating the total cost of the garment.

In the case of footwear business, components are delivered to the production factory usually in-country and the final shoe is shipped in its final packaging to the distribution center, or even direct to the retailer.

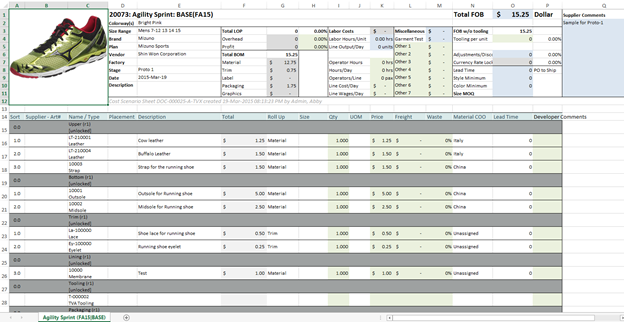

Cost sheets for the footwear business need to track the tooling cost for the production run and amortize the cost across the styles.

Figure 11: Global sourcing calendar for task/style tracking

Figure 12: Advanced cost sheet with tooling amortization

Conclusion

Even though both Apparel and Footwear process are significantly different, traditional PLM vendors can’t offer a hybrid solution to cater to the demands of both industries. TECHNIA resolved this complex business challenge by imperative schema modeling, configurable rule engine and innovative programming techniques.

TECHNIA value-driven process and methodologies are available to the global apparel and footwear customers to execute a single source of truth PLM backbone at a lower cost of ownership.

Discover more about TECHNIA’s PLM solutions for the Apparel industry